Automotive Interiors Expo Europe exhibitors represent the A-Z of car interiors, with our exhibitors’ products being found in vehicles from just about every car manufacturer you can name, from Ferrari, Maserati, McLaren and Porsche through to GM, Volkswagen, Jaguar, BMW, Kia Toyota and Chery to name just a few!

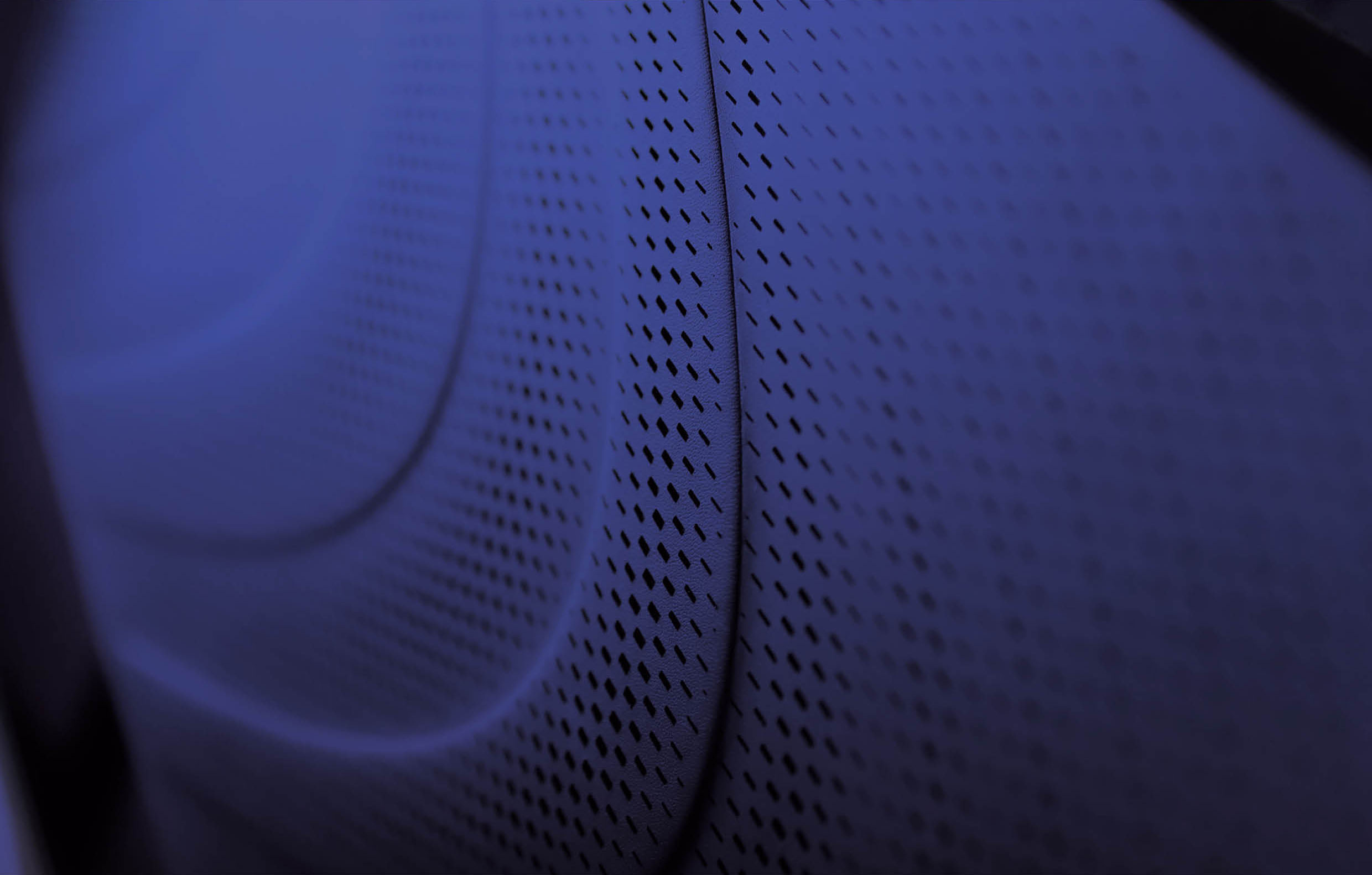

The show is about quality, color, texture, touch, feel and innovation. HMI technologies, Haptics, and specialty finishes are a strong theme of the expo, with some companies offering plastic compounding and master batching, metalized plastics and chrome-look plastics, and others presenting hot foil stamping and film insert molding.

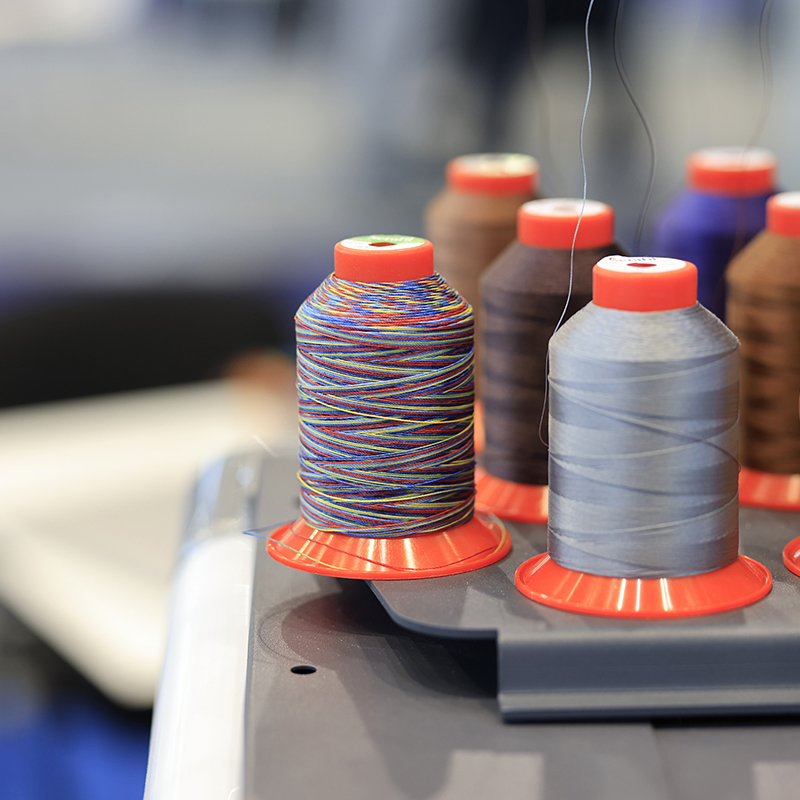

You’ll find a wide range of fabrics, acoustical materials, shape-forming materials and foams, fasteners and adhesive systems, lighting and more! The show is a must-visit for Tier 1 suppliers as well as for interior design teams from car manufacturers wanting to keep up with the rapidly changing world of materials, finishes and technologies that contribute to ‘touch and feel’.

The show is of equal significance to design teams and procurement people, and is full of things to see whether you are working as an interior designer or, just as importantly, as a Tier 1 or 2 component manufacturer. This is a solutions show with a tremendous number of innovative products to see!

Join us in person as we connect, share ideas, find innovation and look to deliver a better, more efficient and sustainable future. Click here to register.

Check our exhibitor interviews from recent events

Landesmesse Stuttgart GmbH

Messepiazza 1

70629 Stuttgart

Germany

+49 711 18560-0